What is the Cam-A-Line Dowel Guide?

The Cam-A-Line Dowel Guide is a self-centering doweling jig designed for precise and repeatable dowel placement in woodworking projects․ Manufactured by Woodpeckers‚ it offers both Inch and Metric guide bushings‚ ensuring compatibility with various dowel sizes․ This tool is ideal for professionals and hobbyists‚ providing a reliable solution for aligning and drilling accurate holes․ Its durable construction and user-friendly design make it a versatile tool for a wide range of woodworking applications‚ from furniture making to cabinet construction․

Importance of Doweling in Woodworking

Doweling is a cornerstone of traditional woodworking‚ offering strong‚ invisible joints essential for furniture and cabinet construction․ Unlike visible fasteners‚ dowels provide a clean finish and exceptional durability․ They enhance structural integrity‚ ensuring projects withstand time and use․ The Cam-A-Line Dowel Guide excels in this process‚ delivering precise alignment and consistent results‚ which are vital for professional-grade woodworking․ Its ability to streamline doweling makes it indispensable for achieving the strength and aesthetics woodworkers strive for in their creations․

Overview of the Cam-A-Line Dowel Guide Features

The Cam-A-Line Dowel Guide is a self-centering doweling jig kit designed for precision and versatility․ It features adjustable spacing for repeatable results‚ guide bushings for accuracy‚ and durable construction for long-lasting performance․ Compatible with various dowel sizes‚ it streamlines the doweling process․ The jig includes a fence and stops for consistent alignment‚ making it ideal for woodworking projects requiring strong‚ invisible joints․ Its robust design ensures stability‚ while its ease of use makes it accessible for both professionals and hobbyists․ A must-have for achieving professional-grade results․

Key Features of the Cam-A-Line Dowel Guide

- Self-centering mechanism for precise alignment

- Adjustable and repeatable spacing

- Guide bushings for accuracy

- Durable construction and materials

- Compatibility with various dowel sizes

Self-Centering Mechanism

Adjustable and Repeatable Spacing

The Cam-A-Line Dowel Guide offers adjustable and repeatable spacing‚ allowing woodworkers to achieve consistent results․ Its precise mechanism ensures accurate alignment‚ making it ideal for projects requiring uniform dowel placement․ The guide’s adjustability accommodates various project needs‚ while its repeatability saves time and effort; This feature is particularly advantageous for creating uniform joints in furniture‚ cabinets‚ and shelving․

Guide Bushings for Precision

The Cam-A-Line Dowel Guide features high-quality guide bushings that ensure pinpoint accuracy and consistency in doweling․ These bushings are crafted from durable materials‚ such as hardened steel‚ to withstand frequent use and maintain precision․ Available in various sizes‚ they accommodate different drill bits and dowel diameters‚ making the guide versatile for diverse woodworking projects․ The bushings’ snug fit prevents drill bit deflection‚ ensuring perfectly aligned holes every time․ This feature is crucial for achieving professional-grade joints in furniture‚ cabinetry‚ and shelving․ By maintaining consistent alignment and reducing the risk of errors‚ the guide bushings enhance the overall efficiency and quality of woodworking tasks․

Durable Construction and Materials

The Cam-A-Line Dowel Guide is built with rugged‚ high-quality materials to ensure long-lasting performance․ Constructed from durable aluminum and steel components‚ it withstands the demands of frequent use in woodworking projects․ The robust design ensures stability and precision‚ even in heavy-duty applications․ Its anodized finish resists wear and corrosion‚ maintaining its reliability over time․ This tool is designed to endure workshop conditions‚ providing consistent accuracy and durability for years of reliable service․ Its solid construction makes it a worthwhile investment for woodworkers seeking lasting precision․

Compatibility with Various Dowel Sizes

The Cam-A-Line Dowel Guide accommodates a wide range of dowel sizes‚ ensuring versatility for different woodworking projects․ With interchangeable guide bushings available in both Inch and Metric sizes‚ it supports dowels from 1/4″ to 1″ in diameter․ This adaptability makes it suitable for various applications‚ from small furniture pieces to large-scale constructions․ Whether using standard or metric dowels‚ the guide ensures precise alignment and consistent results‚ catering to diverse woodworking needs and preferences․ This feature enhances its utility across multiple projects and materials․

How the Cam-A-Line Dowel Guide Works

The Cam-A-Line Dowel Guide ensures precise dowel alignment and drilling through its self-centering mechanism and guide bushings․ It aligns workpieces accurately‚ allowing for consistent and repeatable results in woodworking projects․

Alignment and Setup Process

Aligning the Cam-A-Line Dowel Guide begins with securing the workpiece firmly on a flat surface․ The jig’s self-centering mechanism ensures accurate alignment by automatically positioning the drill bit in the center of the dowel hole․ Users can calibrate the guide using reference edges or marks on the workpiece for precise placement․ The guide bushings are then adjusted to the desired spacing‚ ensuring consistent and repeatable results․ Clamping the jig firmly prevents movement during drilling‚ making the setup process straightforward and reliable for achieving professional-grade accuracy in woodworking projects․

Drilling Accurate Holes

Drilling accurate holes with the Cam-A-Line Dowel Guide is straightforward due to its self-centering mechanism and precision guide bushings․ The jig ensures the drill bit remains steady‚ aligning perfectly with the dowel hole․ Using a sharp drill bit‚ such as a Forstner bit‚ helps achieve clean‚ precise holes․ Maintain consistent pressure and avoid applying too much force‚ which could cause the bit to wander․ This method ensures perfectly aligned and accurately sized holes for dowels‚ resulting in strong and professional-looking joints in woodworking projects․

Clamping and Securing the Workpiece

Clamping and securing the workpiece is crucial for precise doweling․ The Cam-A-Line Dowel Guide requires a stable workpiece to ensure accurate hole alignment․ Use high-quality clamps or a vise to firmly hold the material in place․ Tight clamping prevents movement during drilling‚ which could lead to misaligned holes․ Ensure the workpiece is flat and even before clamping to maintain proper contact with the guide․ Additional clamping devices‚ such as F-style clamps‚ can provide extra stability for larger or irregularly shaped materials․

Advantages of Using the Cam-A-Line Dowel Guide

Clamping and securing the workpiece is essential for precise doweling․ Use clamps or a vise to hold materials firmly‚ preventing movement during drilling․ Ensure the workpiece is flat and evenly aligned with the guide; Proper clamping prevents misaligned holes and enhances accuracy․ For larger or irregular materials‚ additional clamps like F-style clamps can provide extra stability‚ ensuring the workpiece remains stationary throughout the process․ Secure clamping is key to achieving professional-grade results with the Cam-A-Line Dowel Guide;

Improved Accuracy in Doweling

The Cam-A-Line Dowel Guide enhances accuracy by aligning holes perfectly with its self-centering mechanism․ Guide bushings prevent drill bit deflection‚ ensuring precise placement․ Adjustable and repeatable spacing eliminates guesswork‚ while the jig’s rigid construction maintains stability․ This tool is ideal for projects requiring exact alignment‚ such as furniture frames or cabinets‚ delivering professional-grade results․ Its design minimizes errors‚ making it a reliable choice for woodworkers seeking consistent and accurate doweling outcomes in various woodworking projects․

Time-Saving Benefits

The Cam-A-Line Dowel Guide streamlines woodworking projects by reducing setup and alignment time․ Its self-centering mechanism quickly aligns holes‚ eliminating manual measurements․ Adjustable and repeatable spacing ensures consistent results without recalibrating for each hole․ The durable construction and compatibility with various dowel sizes minimize tool changes‚ saving time during production․ Guide bushings enhance precision‚ reducing errors and the need for retries․ This tool is designed to maximize efficiency‚ allowing woodworkers to complete projects faster while maintaining high-quality outcomes․ Ideal for both professionals and hobbyists seeking to save time without compromising accuracy․

Versatility for Different Woodworking Projects

The Cam-A-Line Dowel Guide excels in various woodworking projects‚ from building tables and shelves to constructing cabinets‚ drawers‚ and furniture frames․ Its adjustable spacing and self-centering mechanism make it ideal for both small and large-scale tasks․ Whether creating precise joints for cabinetry or aligning dowels for sturdy furniture‚ the guide adapts seamlessly to different project requirements․ Its compatibility with various dowel sizes ensures versatility‚ making it a go-to tool for woodworkers tackling diverse and complex designs with ease and precision․

Enhanced Stability and Precision

The Cam-A-Line Dowel Guide ensures enhanced stability and precision through its self-centering mechanism and interchangeable guide bushings․ These features allow for accurate hole alignment and consistent dowel placement‚ reducing errors and improving joint strength․ The durable construction maintains stability during use‚ while the precise guide bushings prevent drill bit deflection․ This combination enables woodworkers to achieve professional-grade results with ease and confidence in their projects․

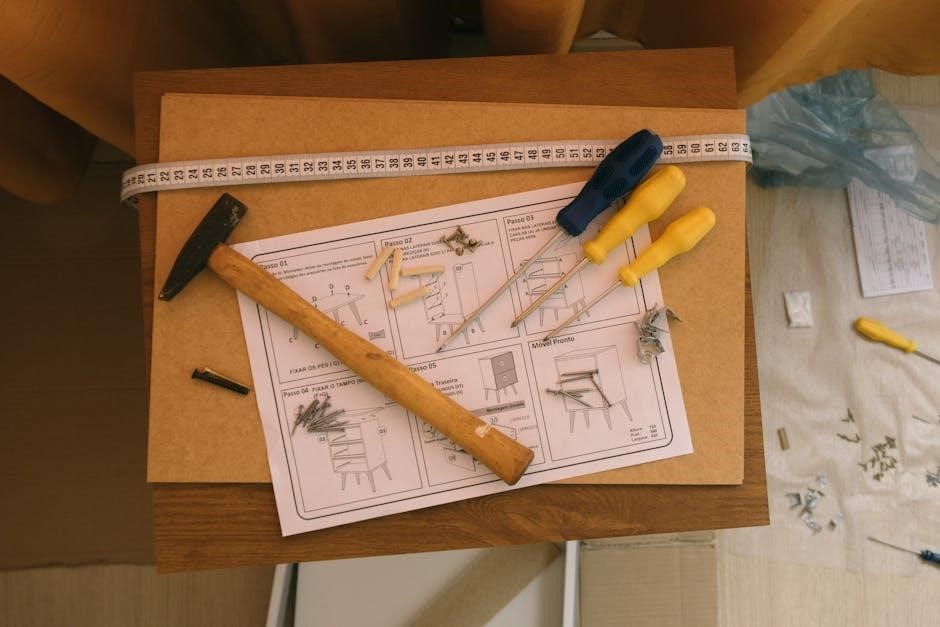

Setting Up and Using the Cam-A-Line Dowel Guide

Unbox and calibrate the guide for your workpiece‚ ensuring precise alignment․ Follow best practices for first-time users to achieve accurate results and maximize tool performance․

Unboxing and Initial Setup

Unboxing the Cam-A-Line Dowel Guide reveals a well-organized kit with the jig‚ guide bushings‚ and instructions․ Initial setup involves attaching the jig to your workpiece or fence‚ ensuring proper alignment․ Calibration is straightforward‚ requiring minimal adjustments to match your project’s specifications․ First-time users should ensure the workpiece is securely clamped and the jig is properly seated for accurate results․ The process is designed to be user-friendly‚ allowing quick setup and precise doweling right out of the box․

Calibrating the Guide for Your Workpiece

Calibrating the Cam-A-Line Dowel Guide ensures precise alignment with your workpiece․ Start by mounting the jig to your workbench or fence‚ then adjust the guide bushings to match your dowel size․ Use the self-centering mechanism to align the jig with your material‚ ensuring proper registration․ Fine-tune the stops for consistent spacing and test the setup on scrap wood to confirm accuracy․ This step ensures your project’s dowel holes are perfectly positioned and aligned‚ saving time and improving results․

Best Practices for First-Time Users

For first-time users of the Cam-A-Line Dowel Guide‚ start by carefully reading the manual to understand its features and operation․ Plan your project and mark the workpiece accurately before setting up the jig․ Use masking tape to align holes for dowels‚ ensuring proper placement․ Always clamp the workpiece securely to prevent movement during drilling․ Practice on scrap wood to refine your technique and confirm the guide’s calibration․ This approach ensures a smooth and accurate doweling experience‚ helping you achieve professional-quality results from the start․

Common Mistakes to Avoid

- Misaligning the guide‚ leading to uneven dowel placement․

- Using improper drilling techniques‚ causing inaccurate holes․

- Over-tightening the jig‚ which can damage the workpiece․

- Ignoring material preparation‚ resulting in poor dowel fit․

Misalignment of the Guide

Misalignment of the Cam-A-Line Dowel Guide is a common mistake that can lead to uneven dowel placement and inaccurate joints․ This often occurs when the guide is not properly secured or calibrated to the workpiece․ To prevent misalignment‚ ensure the jig is clamped firmly and aligned with the material’s edge․ Double-check the guide’s position before drilling․ Using a sharp spade bit and ensuring the drill is perpendicular to the workpiece can also help maintain accuracy․ Proper setup is key to achieving precise results․

Improper Drilling Techniques

Improper drilling techniques can compromise the accuracy and strength of dowel joints․ Using a dull drill bit or applying excessive pressure can cause the bit to wander‚ leading to misaligned holes․ Always use sharp‚ high-quality bits‚ such as a Forstner or spade bit‚ to ensure clean‚ precise cuts․ Maintain a steady hand and keep the drill perpendicular to the workpiece․ Starting with a pilot hole slightly smaller than the dowel size helps prevent splitting and ensures a snug fit․ Proper drilling practices are essential for achieving professional-quality results with the Cam-A-Line Dowel Guide․

Over-Tightening the Jig

Over-tightening the Cam-A-Line Dowel Guide can restrict its self-centering mechanism‚ leading to misalignment and uneven pressure on the workpiece․ This can result in skewed dowel holes or damage to the jig itself․ To avoid this‚ tighten the jig just enough to secure it firmly without applying excessive force․ Always ensure the guide is properly calibrated and aligned before drilling․ Over-tightening can compromise accuracy and longevity‚ so gentle yet secure fastening is key for optimal performance and durability of the Cam-A-Line Dowel Guide․

Ignoring Material Preparation

Ignoring material preparation is a common mistake that can lead to poor joint quality and misaligned dowels․ Always ensure your workpiece is properly planed‚ sanded‚ and free of debris before using the Cam-A-Line Dowel Guide․ Wood that is warped‚ uneven‚ or damp can cause inaccurate alignment and drilling․ Proper material preparation ensures the jig performs optimally‚ delivering precise and professional results․ Neglecting this step can result in subpar joints and potential damage to your tools or workpiece․ Always prioritize preparation for the best outcomes․

Projects Best Suited for the Cam-A-Line Dowel Guide

The Cam-A-Line Dowel Guide excels in projects requiring precise alignment‚ such as building tables‚ shelves‚ cabinets‚ and chairs․ Its versatility makes it ideal for both professionals and DIYers‚ ensuring accurate doweling for strong and durable joints in various woodworking tasks․

Building Tables and Shelves

The Cam-A-Line Dowel Guide is ideal for building tables and shelves‚ ensuring precise alignment of legs and surfaces․ Its self-centering mechanism and adjustable spacing feature allow for accurate doweling‚ creating strong and durable joints․ Perfect for projects requiring multiple pieces to be joined at once‚ the guide streamlines the process‚ saving time and enhancing stability․ Woodworkers can achieve professional-grade results with ease‚ making it a go-to tool for furniture projects that demand precision and reliability․

Creating Cabinets and Drawers

The Cam-A-Line Dowel Guide excels in creating cabinets and drawers‚ offering precise alignment for drawer slides and cabinet shelves․ Its adjustable spacing and self-centering mechanism ensure strong‚ durable joints‚ while guide bushings maintain accuracy․ Ideal for projects requiring multiple pieces‚ it simplifies assembly and enhances stability․ Woodworkers can achieve professional-grade results with ease‚ making it a go-to tool for cabinetry projects that demand precision and reliability․ Perfect for both small and large-scale cabinet constructions․

Constructing Chairs and Furniture Frames

The Cam-A-Line Dowel Guide is ideal for constructing chairs and furniture frames‚ ensuring precise and durable joints․ Its self-centering mechanism and adjustable spacing make it perfect for aligning legs‚ seats‚ and backrests․ The guide bushings provide accuracy‚ while the durable construction withstands heavy use․ Woodworkers can efficiently create stable and professional-looking furniture pieces‚ from modern chairs to intricate frames‚ with ease and confidence‚ thanks to the guide’s versatility and reliability in woodworking projects․

Comparing the Cam-A-Line Dowel Guide to Other Tools

The Cam-A-Line Dowel Guide stands out among tools like Dowel Max and Triton Duo-Doweller‚ offering a self-centering mechanism and durable construction for precise woodworking․ Its adjustable spacing and compatibility with various dowel sizes make it a versatile choice for professionals and hobbyists‚ ensuring consistent results in furniture making and other woodworking projects․

Dowel Max vs․ Cam-A-Line

The Dowel Max and Cam-A-Line Dowel Guide are both popular choices for woodworking‚ but they differ in design and functionality․ The Cam-A-Line is known for its self-centering mechanism and adjustable spacing‚ making it highly versatile for various projects․ In contrast‚ the Dowel Max is praised for its simplicity and ease of use‚ though it may lack the precision and adaptability of the Cam-A-Line․ Woodworkers often choose the Cam-A-Line for its durability and compatibility with multiple dowel sizes‚ while the Dowel Max is preferred for its straightforward setup and portability․ Both tools excel in their respective areas‚ catering to different needs and preferences in woodworking․

Triton Duo-Doweller vs․ Cam-A-Line

The Triton Duo-Doweller and Cam-A-Line Dowel Guide are distinct in their approach to doweling․ The Cam-A-Line is a self-centering jig with adjustable spacing and precision guide bushings‚ ideal for repetitive tasks․ The Triton Duo-Doweller‚ while affordable‚ is a handheld tool offering less precision but greater portability․ The Cam-A-Line’s durability and versatility make it a favorite among professionals‚ whereas the Triton appeals to hobbyists seeking a budget-friendly option with decent performance for smaller projects․ Each caters to different needs and budgets in woodworking․

Manual vs․ Automated Doweling Tools

Manual tools like the Cam-A-Line Dowel Guide offer precision and control‚ relying on user skill for accuracy․ They are cost-effective and ideal for small to medium projects․ Automated tools‚ while more expensive‚ provide faster workflows and reduced human error‚ making them suitable for large-scale production․ The choice between manual and automated depends on project size‚ budget‚ and desired speed‚ with manual tools excelling in customization and portability‚ while automated systems prioritize efficiency and consistency in high-volume tasks․

User Reviews and Testimonials

Woodworkers praise the Cam-A-Line Dowel Guide for its precision and durability‚ with many highlighting its ease of use and versatility in various woodworking projects․ While some note minor drawbacks‚ overall satisfaction remains high among users․

Positive Feedback from Woodworkers

The Cam-A-Line Dowel Guide has received widespread acclaim for its exceptional precision and ease of use․ Woodworkers highlight its self-centering mechanism and repeatable results‚ making it a game-changer for consistent doweling․ Many praise its durable construction and versatility‚ adapting seamlessly to various projects․ The ability to handle both Inch and Metric sizes is a significant plus․ Users also commend its compatibility with different dowel sizes‚ ensuring accuracy and efficiency in woodworking tasks․ Its sturdy design and user-friendly features make it a favorite among professionals and hobbyists alike․

Common Praise for Precision and Durability

Criticisms and Areas for Improvement

Future Trends in Doweling Technology

Integration with CNC Machines

Smart Alignment Systems

Eco-Friendly and Sustainable Materials

Final Thoughts on the Cam-A-Line Dowel Guide

Recommendations for Potential Buyers

The Future of Doweling in Woodworking

The future of doweling in woodworking lies in integration with advanced technologies like CNC machines and smart alignment systems․ Tools like the Cam-A-Line Dowel Guide are expected to evolve‚ incorporating automation and eco-friendly materials for sustainable practices․ As woodworking becomes more precise‚ tools will adapt to meet the demands of modern craftsmanship‚ ensuring durability and efficiency․ This evolution will continue to redefine doweling‚ making it more accessible and precise for woodworkers of all skill levels․